Fila X, FDM 3D printing, Filament Maker, Machine, Plastic

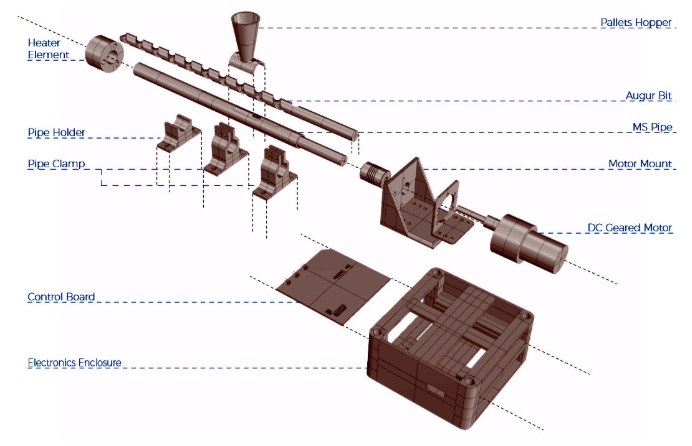

Plastic granules will be pushed mechanically by augur screw in the cylinder, which is powered by the stepper motor. In the end, there will be a PID controlled heater to melt granules. Melted thermoplastic will be extruded through the nozzle of 2.85/1.75 mm diameter and cooled down to get filament form.

NEMA23 is planned to be used in here. It is used to rotate augur screw so that you can control material flow rate by controlling motor RPM. In order to melt plastic granules PID based heater is used so you can have adjustable temperature settings.

Fila X is a simple plastic extruder DIY (Do It Yourself) based machine, which accepts plastic pallets as raw material and extruder FDM printing filament.

Fabrication process:

- 3D printing- Motor and pipe holders

- Laser Cutting- Structure casting and base

- Molding and Casting- Heater mount module

- Electronics design and production- Design a control board

- Embedded programming- Program for input (Thermistor) and output devices (Heater and Motor)

Fabrication Techniques:

- 3D printing – Material feeding hopper

- CNC milling – Base platform and kickback part

- Laser cutting – Product casings

- Electronics design and production

- Embedded programming

- Molding and casting

Tanvir Khorajiya has made this project

Read more…